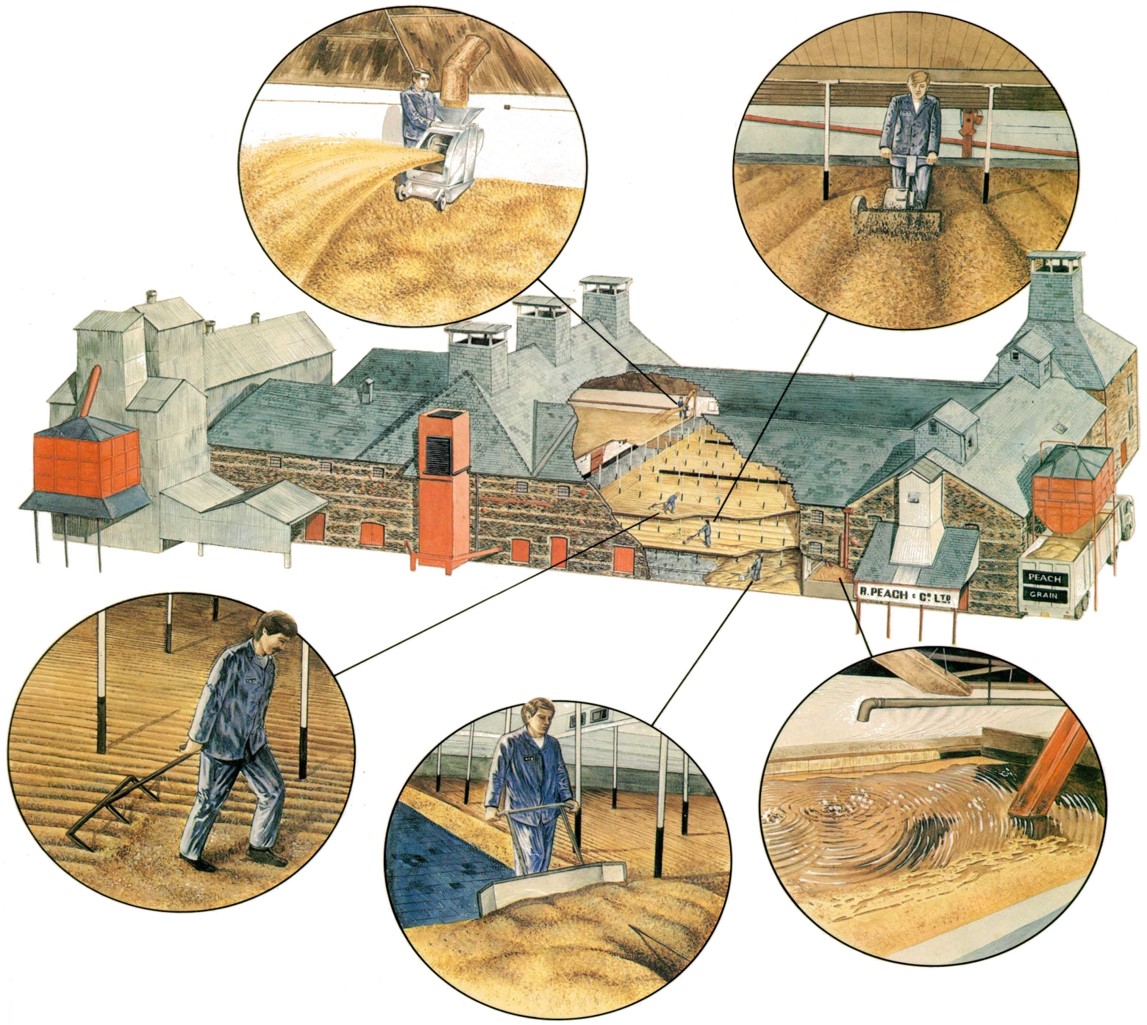

The traditional way to make malt was in a floor malting. After the grain had been soaked in water sufficiently to start germination, the growing grain was spread out on large floor areas. The depth of grain on the floor was thickened or thinned to control the temperature of the growing grain.

Germinating grain produces heat, so this had to be dissipated by turning or raking the grain. When the malt was sufficiently modified it was loaded to the kiln, which had a tall cone shaped roof to produce a natural air draught through the drying malt.

Traditional malt kilns were very energy intensive, and used about the same amount of heat to produce a tonne of malt that it took to make a tonne of steel!

In the early floor maltings this work was all done by hand, but some mechanisation was gradually introduced, until by the 1960’s machinery was being used to reduce the amount of manual labour required.